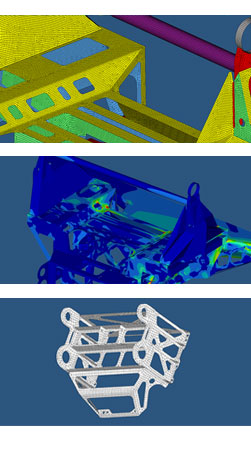

To expedite product development and reduce overall product development costs, our engineers integrate finite element analysis (FEA) principles early in our design process. Through employing FEA principles in the concept development phase, we demonstrate to our clients the structural integrity of our initial concepts. Once the client has selected their preferred concept(s), we then refine those concepts through more in-depth FEA to improve performance. By performing FEA throughout the design process, we are able to verify product feasibility allowing our client’s to focus on solutions that will work and make smart investments with reduced research and development costs.

HALLIDAY LLC can use solid or surface models from popular CAD packages to create the FEA analysis or work from paper drawings. While we predominantly use SolidWorks Premium and Altair HyperWorks software for the analysis, our engineers have experience in all major FEA software codes including Nastran, Patran, Ansys, Femap, MSC Marc, Abaqus, Ardinia, Comsol, FlexPDE, LS-Dyna, SAP2000, STRAND7, Nasgrow, Afgrow and MSC Fatigue.

Our FEA consulting services include:

• Modal • Harmonic response |

• Transient • Conduction • Convection • Radiation • Random vibration • Response spectrum |